This is the fourth post of 3D printing for teens! In this weekly series I will share my experience and tips and tricks. The goal for this series is to get more teenagers excited about 3D printing and to help them master the craft.

In advance

We as Teens don’t have a lot of money to spend. Most 3D printer in the market are above the 1000 euros, the best way to experience 3D printing is building one yourself! Not only will your printer be cheaper you will also gain a lot of experience from it. It may seem daunting at first, but I hope this series will inspire you to start building one yourself. In this post I will cover different printing methods: FDM, SLA and SLS.

Methods

There are many ways to 3D print an object, but you may be surprised how much these 3D printing techniques differ from each other.

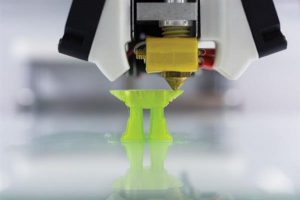

FDM

Fused Deposition Modelling, a technique that melts plastic through an 0.1 – 1mm extruder on a platform. Hobbyists and companies commonly use this method. FDM is the cheapest method and has the biggest market. There a lot of companies that sell filament (the plastic that gets molten) and lots of companies that sell parts and printers. I personally think that FDM will stick around because of the big market. FDM has the advantage that is can take many types of thermoplastics (plastic that can be molten). This leads to acquiring parts that have different physical properties. In my next post I will talk more about making a FDM 3D printer!

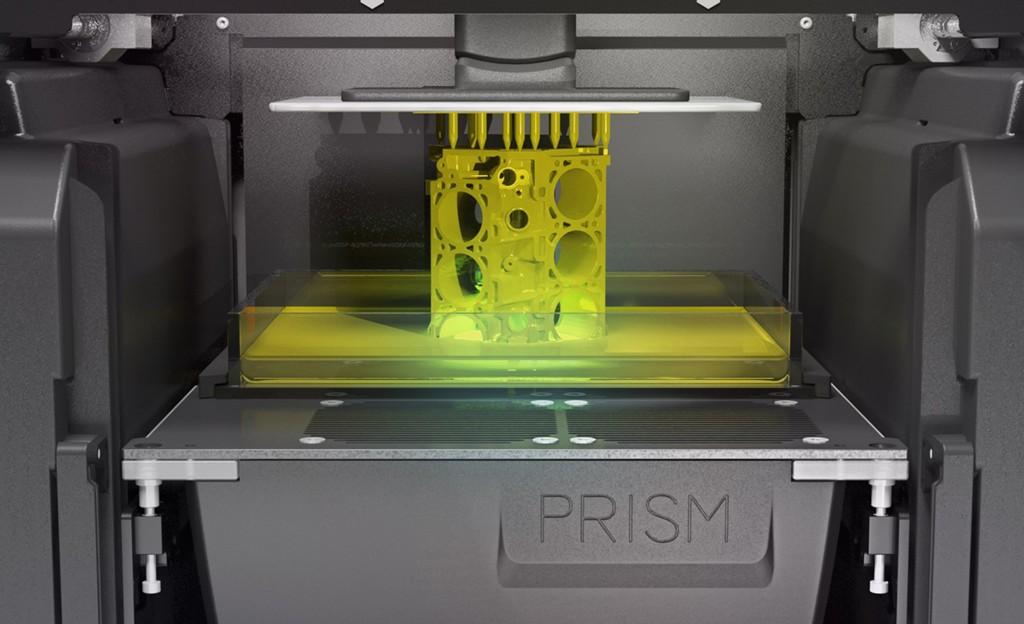

SLA

StereoLithography Apparatus, a technique that focusses a laser in a resin. That resin will harden. It uses a laser, and this will increase the details of your print because your print is no longer dependant on the diameter of the extruder hole but dependant on the thickness of the laser beam. But this technique has a few disadvantages:

- The resin is poisonous and when the print is finished it needs te be cleaned and cured a little further in the sun. This is a longer process for finishing a print.

- It contains a laser and therefor will be more expensive.

- Your material is a chemical resin, this will limit your options of materials to choose from.

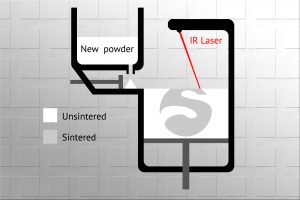

SLS

Selective Laser Sintering, a technique that focusses a laser on powder that will melt into a solid product. I my opinion this technique is the best one: SLS can produce very complex shapes because it is not dependant on support structures. The sintering powder around the shape already acts as a support for the object. SLS supports a lot of material form nylon to steal. This all depends on the laser that your printer supports. The only disadvantages I can think of is the price, the rough surface it will create and the now complex machines which will become better in the future. In conclusion, SLS 3D printers will become the new standard! When the price drops.

In conclusion

FDM, SLA and SLS are the most popular 3D printing techniques in the market. FDM and SLS are the best methods overall. In my next post I will discuss how to build your first 3D printer! This printer will be a FDM printer because they are the cheapest to build!

Next post

An in-depth look into FDM printing.

Get 3D printed headphones: click here

Visit the shop: click here