This is the sixth post of 3D printing for teens! In this weekly series I will share my experience and tips and tricks. The goal for this series is to get more teenagers excited about 3D printing and to help them master the craft.

In advance

We as Teens don’t have a lot of money to spend. Most 3D printer in the market are above the 1000 euros, the best way to experience 3D printing is building one yourself! Not only will your printer be cheaper you will also gain a lot of experience from it. At first it may seem daunting, but I hope this series will inspire you to start building one yourself. In this post I will go into detail of the x,y,z axis.

Into detail

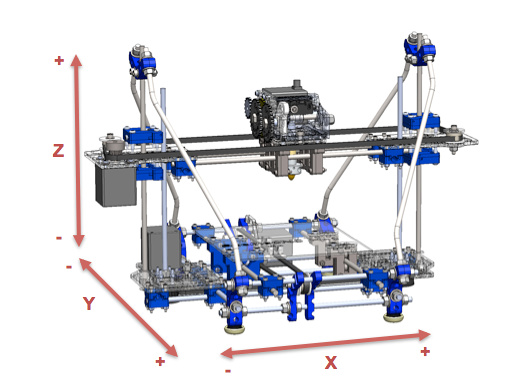

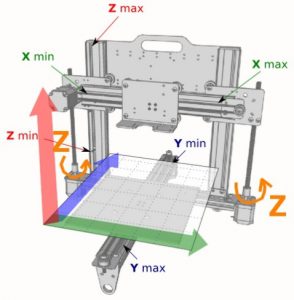

The x,y,z axis is the component that lets the extruder move from a to b. The x,y,z axis contains stepper motors that will move to extruder to the coordinate it needs to go. It is important for the extruder to move freely in the axis grid; the moving parts use linear ball bearings.

You can configure your own axis configuration, but the extruder has to be able to move freely in all three directions. The parts you usually use for the axis are

- leadscrews

- bearings

- linear sliders

- engine clutches

- pulleys

- belts

- metal rod

- turning ends

You also need to decide which stepper motor to use, different stepper motors have different step resolutions. We usually use 1.8 degrees per step, that’s equivalent to 200 steps per full rotation. Fun fact: there is a high chance that your stepper motor’s name contains something with NEMA, which stands for National Electrical Manufacturers Association. This specifies the square width of the motor. For example: a NEMA 17 stepper has a width of 1.7 inch. For 3D printing we use NEMA 17 stepper motor because they have a low chance of overheating!

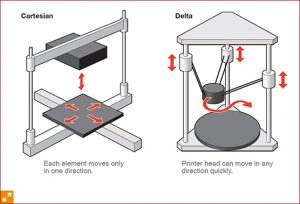

Cartesian vs Delta

After looking at a few printers you will see a cube type style of printer and long three arm printers. In the 3D printing world, the most common types of printers are cartesian en delta printer. Cartesian are printers with 3 direction: x,y,z. Cartesian printers are mechanically simple and relatively easy from a software perspective because it uses cartesian coordinates. Delta printers use a three-arm system with a z direction. Delta printers have the advantage in the ability to make taller objects because of the height of the printer with the tall arms but needs a beefier CPU because they need to make more complex calculations. I have a cartesian style printer myself. Delta printers are going to be more expensive but if you want speed go for it.

To sum up

In this post I gave a list of components to use and information about stepper motors and cartesian and delta printers.

Next post

I will go in depth into extruders.

Excellent review, much more useful than those other reviews on Indian sites!